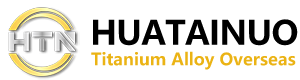

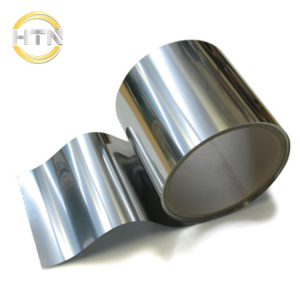

Gr2 Titanium Foil ASTM F67

Item: Titanium Foil.

Material: Titanium Gr1, Gr5.

Size: 0.1mm+/-0.02mm.

Width: 400mm+/0.1mm.

Standards: ASTM B265, ASTM F136, ASTM F67, GB/T 3621-2007.

Finish: Polishing, Annealed, R, Y, M.

|

|

Details

- Item: Titanium Foil

- Material: Titanium Gr1, Gr5.

- Size: 0.1mm+/-0.02mm

- Width: 400mm+/0.1mm

- Standards: ASTM B265, ASTM F136, ASTM F67, GB/T 3621-2007

- Finish: Polishing, Annealed, R, Y, M.

Product Description

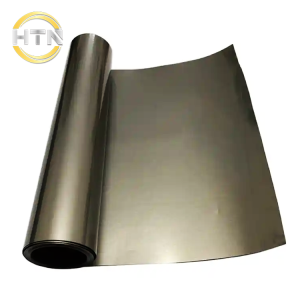

Producing titanium foil as thin as 0.007 inches demands advanced equipment and deep technical expertise. As a leader in titanium foil manufacturing, we specialize in custom-engineered solutions tailored to your precise specifications.

Ease of Fabrication

Pre-processing during foil formation enhances titanium’s ductility and workability, expanding its suitability for diverse applications such as machinery, aerospace, transportation, automotive, sports equipment, and medical devices.

Vibration Damping Performance

Gr1 titanium foil exhibits excellent vibration damping characteristics. Its vibration attenuation time surpasses that of steel and copper, making it ideal for applications including tuning forks, medical ultrasonic mill vibration elements, and high-end speaker diaphragms.

Heat Treatment Methods

We employ two primary heat treatment processes:

- Vacuum Annealing: Batch processing of rolled foil in a vacuum furnace.

- Continuous Online Protective Annealing: A modern technique offering higher production efficiency and superior consistency in product quality and mechanical properties.

Corrosion Resistance

Titanium demonstrates outstanding corrosion resistance, remaining unaffected by atmospheric exposure, seawater, and chemicals including:

- ≤7% hydrochloric acid

- ≤5% sulfuric acid

- Nitric acid

- Aqua regia

- Dilute alkaline solutions

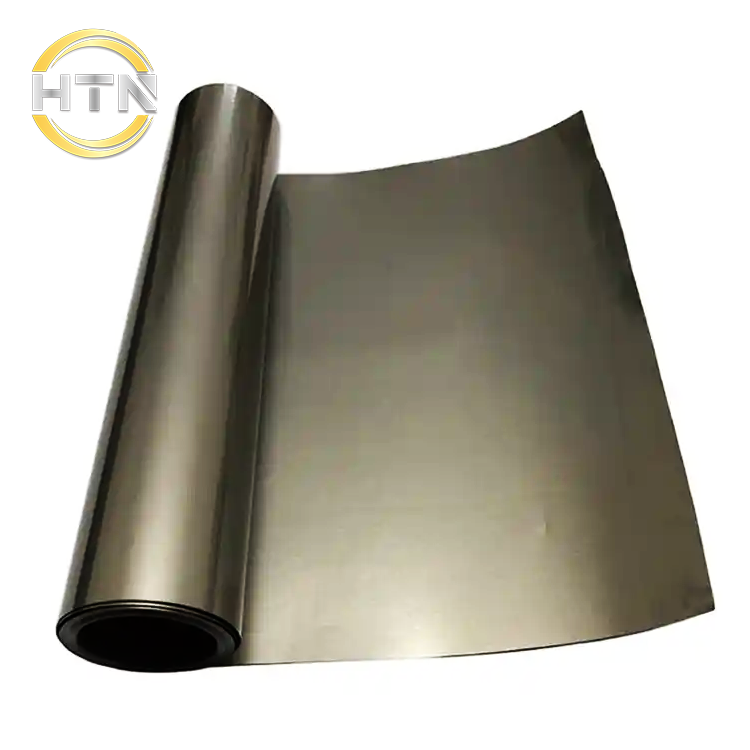

Industry Applications

Titanium foil in coil form serves numerous sectors including electronics, chemical processing, watchmaking, eyewear, jewelry, sports equipment, machinery, electroplating devices, environmental protection, golf, medical, and precision manufacturing.

Key Features

- Exceptional corrosion resistance

- Low elastic modulus

- Superior heat exchange performance

- Non-magnetic properties

- Hydrogen absorption capability

- Wide temperature tolerance

- Non-toxic composition

Quality Control

Our comprehensive inspection protocol includes:

- Visual surface examination to eliminate defects

- Chemical composition verification

- Mechanical property testing

Quality Assurance

All production complies with international standards including ASTM, AMS, ASME, JIS, and MIL. Our skilled team and specialized equipment enable production of ultra-thin foil down to 0.01mm, with expertise in critical application development and production challenges. We supply both annealed and tempered titanium foil to your exact requirements.

Advanced Applications

Titanium foil serves as an optimal substrate for growing titanium oxide nanotubes via anodization, facilitating the fabrication of TiO₂ thin films and hydroxyapatite/graphene bioactive coatings. Its unique properties make it indispensable for:

- Electrochemical catalysis

- Aerospace engineering

- Biomedical implants

The material combines excellent strength-to-weight ratio, biocompatibility, and appropriate Young’s modulus for demanding applications across aerospace, automotive, medical, electronics, and chemical processing industries.