Advanced Production equipment

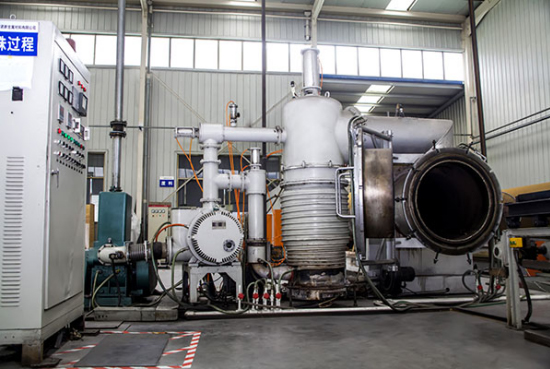

| German ALD Vacuum Arc Furnace – Key Technical Features FAC – Fully Automatic Control The entire melting process, from arc ignition to solidification, is fully automated. This eliminates manual intervention and ensures consistent, high-quality ingot production. MCD – Multi-Contact Conductive Design A fully coaxial power supply system is adopted throughout the melting process. This design cancels adverse inductive magnetic field effects on alloy quality while improving electrical efficiency. DDS – Dual Motor Drive System Ensures precise electrode feed control during melting. This enhances physicochemical reactions and contributes to superior surface quality of the ingot. SCR – Semiconductor Controlled Rectifier ALD’s proprietary SCR power system enables high-precision control over melting power. Stable current and voltage output minimize composition deviation, reduce porosity, and promote a dense, uniform crystalline structure. CSS – Constant Melting Speed Control System Supports multiple control modes including voltage stabilization, constant melting speed, and droplet short-circuit control for flexible and precise process management. DAS – Data Acquisition System A powerful system that enables fully automated recording and analysis of the entire melting process, supporting quality traceability and process optimization. SCS – Smelting Pressure Control System Effectively controls the melting atmosphere to reduce the volatilization of low-melting-point elements, improving composition accuracy and material yield. AEP – Automatic Emergency Protection Program Provides comprehensive safety control. In case of unexpected incidents such as water or power failure, the system automatically activates emergency procedures to ensure equipment and process safety. |

| German Bohler MW120×100-4 Precision Wire Rod Mill 1.High Precision & Speed: Achieves rolling accuracy of ±50μm with speeds up to 120 m/min. 2.Advanced Process Capability: Enables fully automated continuous cold rolling and warm rolling of high-performance bars and wire rods. 3.Superior Product Quality: Guarantees exceptional dimensional control and outstanding property consistency. 4.Material Integrity: Significantly reduces the negative impacts of multi-pass hot drawing, including hydrogen embrittlement risks and microstructural damage. |  |

| 4500-Ton Hydraulic Press Our 4500-ton hydraulic press is engineered to deliver exceptional power, precision, and reliability for the most demanding forging and forming applications in aerospace, automotive, and energy sectors. It provides a core solution for manufacturing large, complex components with superior quality and efficiency. 1.Exceptional Structural Rigidity: A robust FEA-optimized frame ensures minimal deformation under full load. The advanced guide system guarantees high precision and prolonged die life. 2.Precision Pressure Control: An electro-hydraulic servo system provides stepless control with ±1% accuracy, ensuring stability for precision forging and consistent output. 3.High-Efficiency Hydraulic System: Variable displacement pumps and servo drives reduce energy consumption and ensure quiet, stable operation even under prolonged heavy loads. 4.Intelligent Operation & Monitoring: The PLC and HMI interface allow for easy recipe management, real-time monitoring, and data acquisition for full process traceability. 5.Comprehensive Safety Protection: Multi-layer safety interlocks, including light curtains and hydraulic circuits, provide complete protection for both personnel and equipment. |

| Precision Straightening Machine Engineered for titanium bars, rods, and wires, this straightening machine delivers exceptional straightness and surface quality, meeting stringent tolerances for aerospace, medical, and high-performance applications. 1.High-precision straightening with minimal deviation; 2.Compatible with various titanium grades and alloys; 3.Heavy-duty construction resistant to spring back; 4.Adjustable pressure, roller position, and speed; 5.Surface-preserving technology prevents marking; 6.Ensures dimensional consistency and straightness; 7.Reduces secondary processing and improves efficiency; 8.Enhances reliability of critical titanium components |  |

| 650 Titanium Plate Rolling Mill Precision-engineered for titanium processing, this rolling mill delivers exceptional flatness, consistent thickness, and superior surface quality – meeting stringent aerospace and medical industry standards. 1.Precision thickness and flatness control 2.Heavy-duty construction for titanium processing 3.Adjustable speed and pressure settings 4.Surface protection system 5.Intuitive operation interface 6.Maintains tight dimensional tolerances 7.Reduces material waste and rework 8.Increases production efficiency 9.Suitable for critical aerospace and medical components |

| Vacuum annealing furnace This vacuum annealing furnace ensures precise heat treatment of titanium materials under controlled atmosphere, delivering superior material properties and surface quality for aerospace, medical, and high-tech applications. 1.Full vacuum atmosphere protection 2.Precise temperature control system 3.Uniform heating distribution 4.Rapid cooling capability 5.Automated process control 6.Eliminates surface oxidation 7.Improves material structure and ductility 8.Ensures consistent batch quality 9.Meets strict industry standards |  |

| 5kg VAR Furnace for Laboratory Designed for R&D and small-batch production, this 5kg vacuum arc remelting (VAR) furnace enables precise melting of titanium and specialty alloys under controlled conditions, ideal for material testing and process development. 1.Compact VAR system for experimental melting 2.Precise atmosphere and temperature control 3.Supports titanium alloy development 4.User-friendly operation interface 5.Reliable safety protection systems 6.Produces high-purity laboratory-scale ingots 7.Enables alloy composition research 8.Provides reliable data for process scale-up 9.Ensures reproducible melting results |

| Precision Grinding Machine Engineered for titanium processing, this grinding machine delivers exceptional surface finish and dimensional accuracy, meeting stringent requirements for aerospace and medical components. 1.High-precision grinding with tight tolerances 2.Optimized for titanium and its alloys 3.Advanced cooling system prevents thermal damage 4.CNC control with user-friendly interface 5.Robust construction for stable operation 6.Superior surface quality and flatness 7.Maintains material integrity 8.Improved production consistency 9.Reduced operational costs |  |

Advanced Detection Equipment

| SUT-DK-TB Automatic Rotary Head Ultrasonic Flaw Detection Machine The SUT-DK-TB ultrasonic fully automatic flaw detection system is designed for pipes and bars with diameters ranging from Ф6.0 mm to Ф40 mm. It performs four-channel longitudinal and transverse wave inspection, enabling the identification of near-surface defects—a capability not commonly available in existing domestic medical material testing equipment. This system can detect defects as small as 0.3 mm in flat bottom hole equivalent, significantly exceeding the current domestic medical bar standard of 1.2 mm. It also achieves a surface detection accuracy of 0.8 × 0.8 × 3 mm for tubes, bars, and wires. With a maximum detection speed of 3 m/min, the equipment ensures high-precision, fully automated inspection while minimizing the influence of human factors on detection accuracy. |

| ODE-C20A4O Optical Surface Automatic Inspection Instrument The ODE-C20A4O optical surface detector delivers high-precision, automated inspection for bars and wires, with the capability to detect specimens as small as Ø4.0 mm. It achieves international advanced standards in the surface inspection of titanium alloy materials. Equipped with high-resolution optical sensing technology, the instrument reliably identifies various surface defects—such as cracks and pits—with a minimum recognizable defect area of 0.01 mm². Operating at speeds of up to 30 m/min, it enables efficient and continuous detection while significantly reducing the risk of human oversight in defect identification. |  |