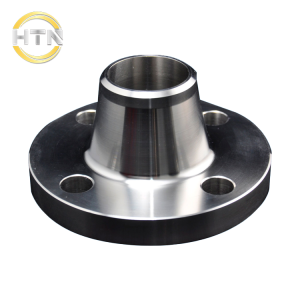

Ti-6Al-4V Titanium Flanges Manufacturer ASME B16.5 & B16.47

Category:

Titanium Machined Part

Grade: Gr5 Ti-6Al-4V

Standards: ASTM B381, ASME B16.5, MIL-DTL-46077G

Size: 1/2″ to 24″ (custom sizes available)

|

|

Details

Product Introduction

Titanium GR-5 flanges, also known as Ti-6Al-4V flanges, are essential components in various high-demand industries. These flanges offer an unparalleled combination of strength, corrosion resistance, and lightweight properties, making them ideal for applications where performance is critical. Our titanium GR-5 flanges are designed to meet and exceed industry standards, providing reliable and long-lasting solutions for your most challenging projects.

Technical Specifications

| Material | Ti-6Al-4V (Grade 5) |

|---|---|

| Tensile Strength | ≥895 MPa |

| Yield Strength | ≥828 MPa |

| Elongation | ≥10% |

| Hardness | 36 HRC (typical) |

| Density | 4.43 g/cm³ |

| Standards | ASTM B381, ASME B16.5, MIL-DTL-46077G |

| Size Range | 1/2″ to 24″ (custom sizes available) |

| Pressure Ratings | 150#, 300#, 600#, 900#, 1500#, 2500# |

Product Features and Advantages

- Superior Strength-to-Weight Ratio: Our titanium GR-5 flanges offer exceptional strength while being 40% lighter than steel alternatives.

- Outstanding Corrosion Resistance: Withstands harsh environments, including seawater and chemical exposure.

- High Temperature Performance: Maintains structural integrity at elevated temperatures up to 400°C (752°F).

- Excellent Fatigue Resistance: Ideal for applications with cyclic loading.

- Biocompatibility: Suitable for medical and food processing industries.

- Low Thermal Expansion: Ensures dimensional stability across a wide temperature range.

Applications

- Aerospace: Engine components, fuel systems, and hydraulic line connections.

- Chemical Processing: Corrosive media handling in reactors and heat exchangers.

- Oil and Gas: Offshore platforms, subsea equipment, and pipeline connections.

- Marine Engineering: Desalination plants and shipbuilding applications.

- Power Generation: Nuclear reactors and high-temperature steam systems.

- Medical Equipment: MRI machines and surgical instruments.