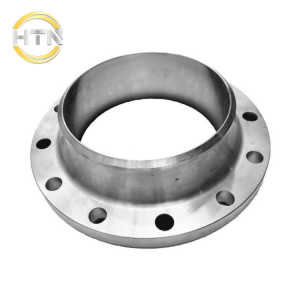

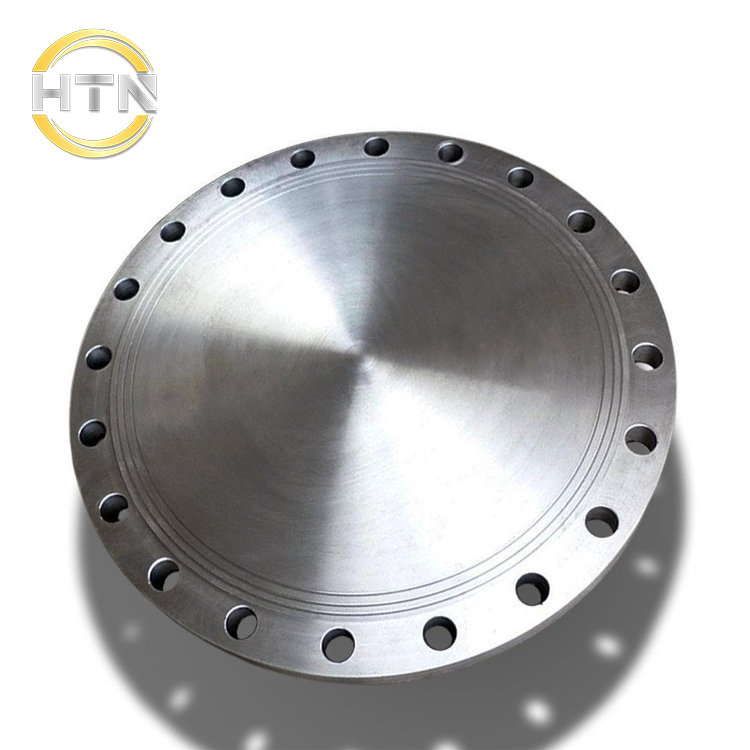

Grade 5 Titanium Blind Flange ASTM B381

Our ANSI titanium blind flanges are engineered for excellence, combining the superior properties of titanium with precision manufacturing. These flanges are designed to provide a secure seal in various high-pressure and corrosive environments, making them ideal for critical applications in industries such as oil and gas, chemical processing, and marine engineering. The use of titanium ensures exceptional corrosion resistance, high strength-to-weight ratio, and long-term durability, even in the most challenging conditions.

|

|

Details

Product Introduction

Our ANSI titanium blind flanges are engineered for excellence, combining the superior properties of titanium with precision manufacturing. These flanges are designed to provide a secure seal in various high-pressure and corrosive environments, making them ideal for critical applications in industries such as oil and gas, chemical processing, and marine engineering. The use of titanium ensures exceptional corrosion resistance, high strength-to-weight ratio, and long-term durability, even in the most challenging conditions.

Technical Specifications

- Material: Grade 2 or Grade 5 Titanium (ASTM B381)

- Size Range: 1/2″ to 24″ NPS

- Pressure Class: 150# to 2500#

- Standards: ANSI/ASME B16.5, ASTM B381

- Hardness: 160-220 HB (Grade 2), 300-400 HB (Grade 5)

- Temperature Range: -196°C to 400°C

- Corrosion Resistance: Excellent against seawater, chlorides, and oxidizing acids

Product Features and Advantages

- Exceptional corrosion resistance in harsh environments

- High strength-to-weight ratio for improved efficiency

- Extended service life, reducing maintenance and replacement costs

- Excellent temperature resistance for diverse applications

- Superior biocompatibility for medical and pharmaceutical use

- Low thermal expansion for stable performance

- Non-magnetic properties ideal for specialized industries