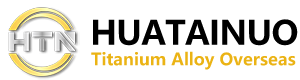

Gr2 Titanium Strip ASTM B265

Gr5, or Ti-6Al-4V, is a versatile alpha-beta titanium alloy renowned for its excellent strength-to-weight ratio and corrosion resistance. It is a primary choice for wrought products like bars, plates, and forgings.

|

|

Details

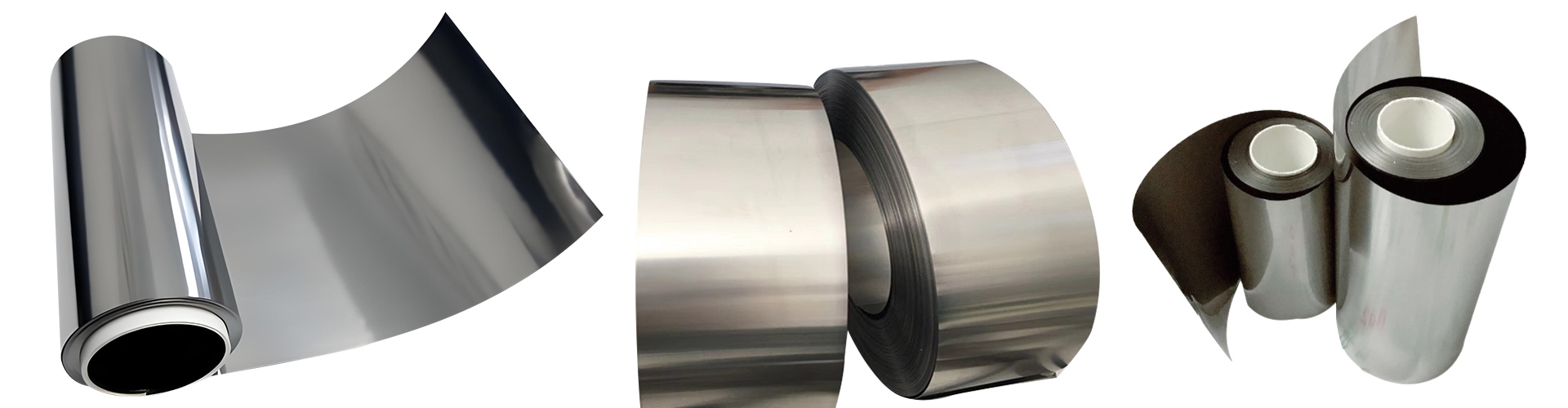

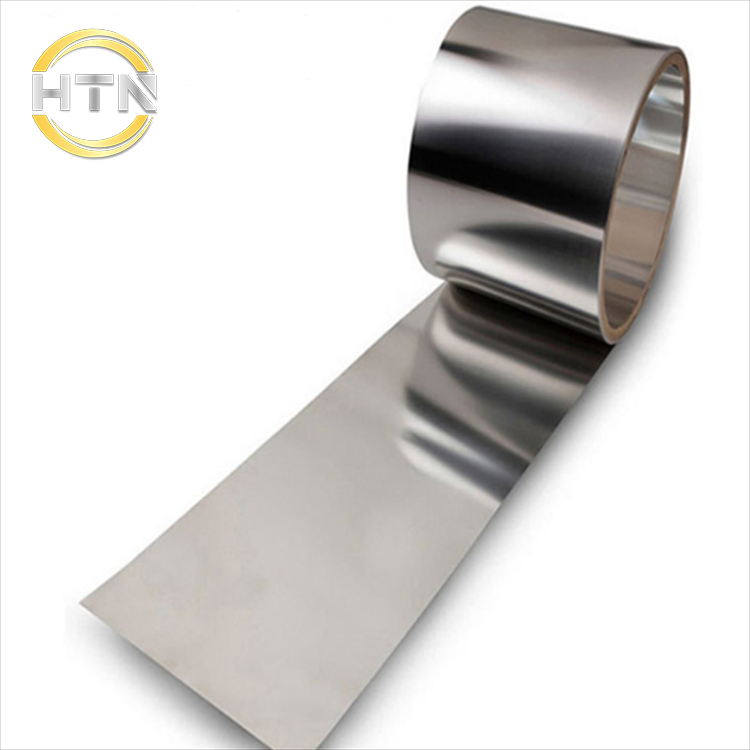

- Item: Gr5 Titanium Strip

- Standard: ASME B265

- Thickness: under 4.75 mm / Customizable

- Width: under 610mm / Customizable

- Length: Up to 6000mm / Customizable

- Finish: Hot Rolling, Cold Rolling.

- Surface: Polished, Sandblasted, Acid Washing.

Product description

- Weight: According To The Actual Weight

- Certificate: ISO 9001:2015

- Packaging: Sponge Padding + Wooden Crate

- Price Term: EXW, FOB, CIF

- Transportation: Ocean, Land, Air

- Delivery Time: 5-25 days.

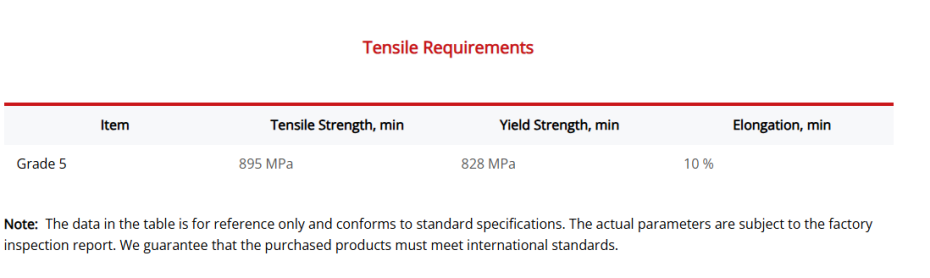

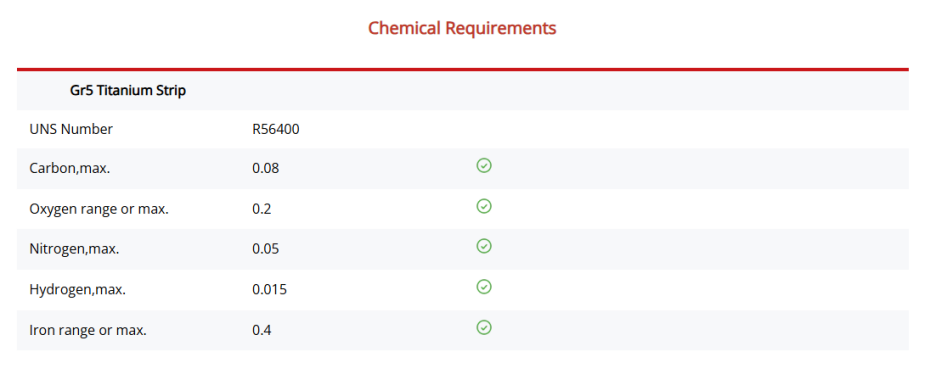

Mechanical properties

Gr5 (Ti-6Al-4V) Titanium Alloy: Overview & Applications

Gr5, or Ti-6Al-4V, is a versatile alpha-beta titanium alloy renowned for its excellent strength-to-weight ratio and corrosion resistance. It is a primary choice for wrought products like bars, plates, and forgings.

Key Characteristics:

Production: Manufactured via advanced melting processes (VAR, EB, PAM) to ensure high purity and homogeneity.

Mechanical Properties: In the annealed condition, it offers a minimum yield strength of 120 ksi. Strength can be further enhanced through solution treatment and aging (STA).

Performance: Exhibits good elevated-temperature strength, low-temperature toughness, and creep resistance.

Corrosion Resistance: Excellent resistance to seawater, marine atmospheres, wet chlorine, and chlorine dioxide.

Fabrication: Readily weldable using inert gas shielding and can be formed with standard methods. Machining is comparable to austenitic stainless steel, requiring slow speeds, heavy feeds, and non-chlorinated cutting fluid.

Gr5 titanium Strip applications

Gr5 Titanium Strip: Engineered for Critical Performance

Trusted in applications from aerospace to medical devices, our Gr5 Titanium Strip meets the rigorous demands of ASME SB 265, AMS 4905, AMS 4911, and DMS 1592 standards.

Why Choose Our Gr5 Titanium Strip?

Proven Safety & Reliability: Ideal for life-critical industries, offering unparalleled resistance to temperature extremes, chemical corrosion, and mechanical stress.

Uncompromising Quality: Manufactured to ensure consistent quality, precise dimensions, and reliable performance in every batch.

Tailored for Your Needs: Beyond standard offerings, we provide customized solutions to meet the unique specifications of your tubes, pipes, and other applications.