Meta Description: This comprehensive guide explains the titanium plate hot rolling process, including slab production, rolling stages, key advantages, and performance optimization for industrial applications.

Introduction to Titanium Plate Applications

A titanium plate is widely recognized for its excellent mechanical strength, low density, and outstanding corrosion resistance. These properties make titanium plates essential materials in industries such as aerospace, chemical processing, marine engineering, and medical devices.

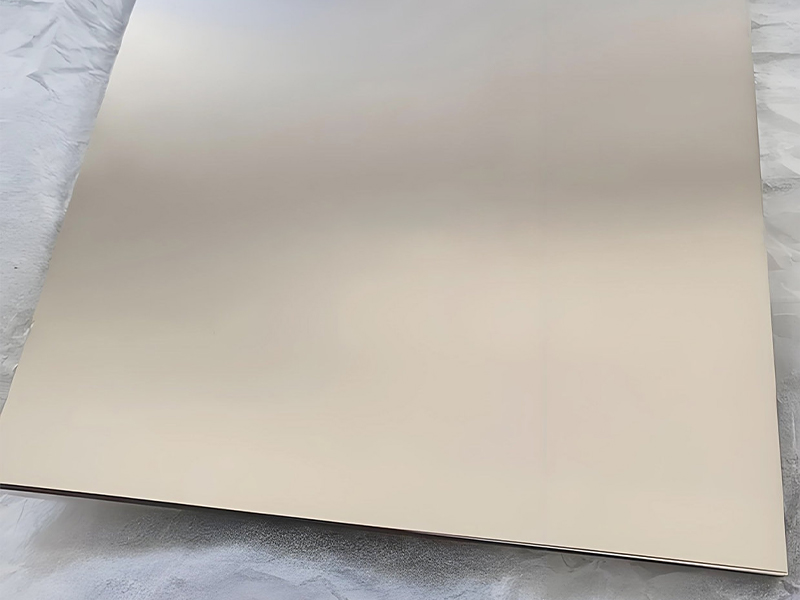

One of the key advantages of titanium plate production is the naturally formed oxide film on the surface. This dense and stable oxide layer acts as a protective barrier, improving wear resistance and eliminating the need for chemical separating agents. As a result, titanium starter sheets simplify plate stripping and reduce pre-treatment steps, significantly improving production efficiency.

As a core material in advanced manufacturing, the production quality of titanium plate depends heavily on the hot rolling process, which we analyze in detail below.

What Is a Titanium Plate?

The term titanium plate broadly refers to several titanium flat products, including:

- Hot-rolled titanium plate

- Cold-rolled titanium plate

- Titanium coil and strip

- Titanium foil

This article focuses specifically on hot-rolled titanium plate, which is the foundation for many downstream titanium products.

Slab Production: From Titanium Ingot to Bloom

All titanium plates originate from titanium ingots, typically weighing 6–10 tons or more for hot rolling applications.

Forging Process

- Large titanium ingots are forged into titanium blooms

- Common bloom dimensions: 210 × 1100 × 8000 mm

Surface Treatment

After forging, the bloom surface contains a thick oxide scale. To ensure surface quality:

- Large gantry milling machines remove oxide layers

- All four sides are milled to create a clean slab suitable for rolling

This step is critical for ensuring dimensional accuracy and preventing surface defects in the final titanium plate.

Titanium Plate Hot Rolling: Core Principles

Hot rolling is performed above the recrystallization temperature of titanium, allowing the metal to deform plastically without excessive work hardening.

A simple analogy is dough being pressed repeatedly to form thin sheets. However, unlike household tools, titanium plate rolling requires precise control of temperature, force, speed, and deformation. Even small deviations can significantly affect mechanical properties and micro-structure.

Four Key Stages in the Titanium Plate Hot Rolling Process

1. Heating the Titanium Slab

- Heating temperature: 900–1000°C

- Soaking time: 4–4.5 hours

- Purpose: ensure uniform internal temperature

Accurate temperature control prevents defects such as coarse grains, uneven micro-structure, or reduced mechanical performance.

2. Rough Rolling (Primary Rolling)

After heating:

- High-pressure water descaling removes surface oxides

- The slab enters a reversible rolling mill (two-high or four-high)

Key objectives:

- Reduce thickness

- Control width and shape

- Prepare the slab for finishing

Stable rolling force and speed during this stage are essential for downstream quality.

3. Finishing Rolling

Finishing determines the final quality of the titanium plate.

- Uses multi-stand mills (e.g., 7-stand four-high mills)

- High-speed rolling with precise reduction control

- Advanced closed-loop shape control systems minimize:

This stage ensures the titanium plate meets strict dimensional and mechanical standards required for high-end applications.

4. Cooling and Coiling

- Laminar flow cooling rapidly reduces temperature

- Cooling rate is adjusted based on:

Proper cooling:

- Optimizes microstructure

- Improves strength and corrosion resistance

After cooling, the titanium plate is coiled, banded, marked, and prepared for storage or further processing.

Key Advantages of the Titanium Plate Hot Rolling Process

1. High Energy Efficiency

Titanium exhibits:

- Low deformation resistance at high temperature

- Minimal work hardening

This reduces rolling energy consumption and lowers overall production costs.

2. High Production Efficiency

Hot rolling supports:

- Large ingot sizes

- High reduction ratios

- Continuous, high-speed production

This makes it ideal for large-scale titanium plate manufacturing.

3. Improved Microstructure and Performance

Hot rolling transforms:

- As-cast structure → wrought structure

Benefits include:

- Better plasticity

- Enhanced workability

- Improved service life

This microstructural refinement expands the application range of titanium plate products.

4. Anisotropic Properties

Due to rolling deformation:

- Mechanical properties vary by direction

- Texture formation affects formability

Designers must consider plate orientation during fabrication to maximize performance.

Gr 5 Titanium Sheet

Future Development of Titanium Plate Hot Rolling Technology

Modern titanium plate hot rolling technology achieves:

- Temperature control at 850–950°C

- Shape tolerance within ±0.1 mm

- Rolling force fluctuation control within ±5%

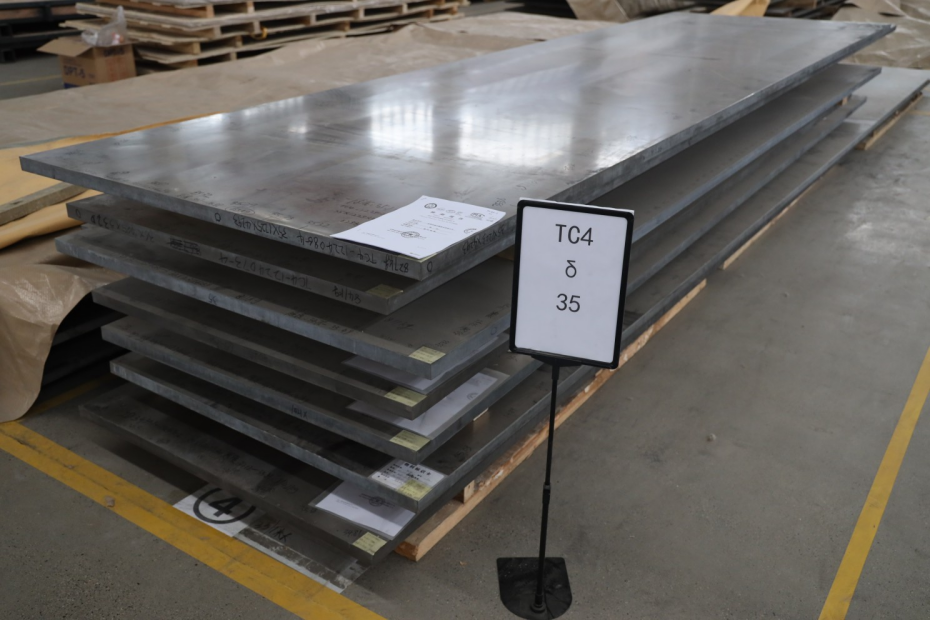

However, growing aerospace demand for high-performance alloys such as TC4 and TA15 requires continuous innovation. Future advancements will focus on:

- Higher strength-to-toughness ratios

- Enhanced microstructure control

- Expanded application fields

Conclusion

The titanium plate hot rolling process is a cornerstone technology in advanced metal manufacturing. Through precise temperature control, multi-pass rolling, and optimized cooling, it delivers titanium plates with superior mechanical properties and reliability.

As industrial demands increase, ongoing innovation in titanium plate production will continue to unlock new possibilities across aerospace, medical, chemical, and marine sectors.

#titaniumplate #titaniumsheets #titaniumalloy #titaniummanufacturer #titaniumproductionprocess