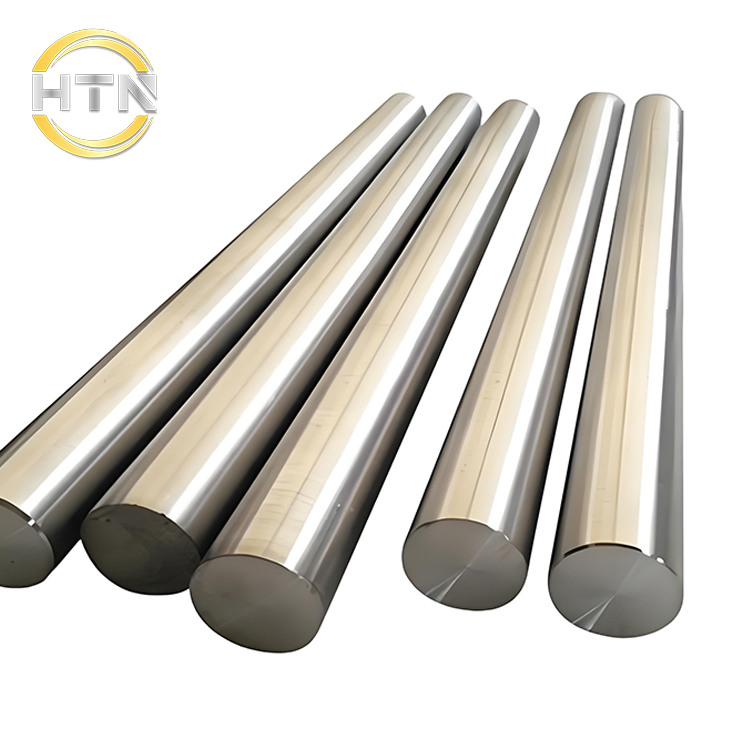

GR1 Titanium Bar ASTM B348

Brand: Titanium.

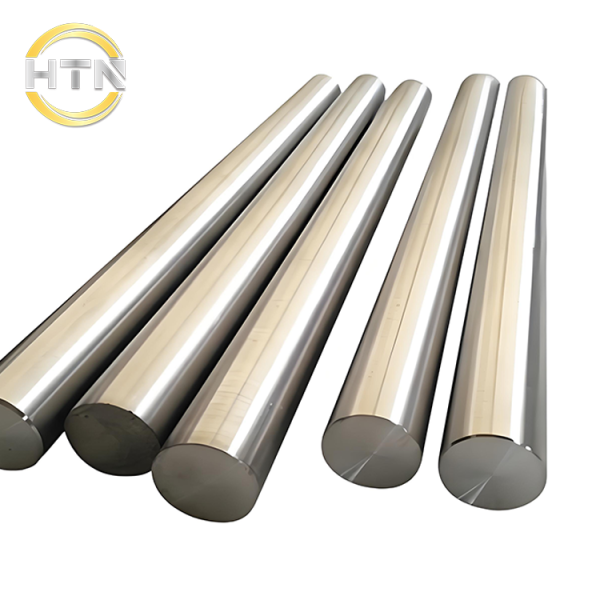

Shape: Round / Square / Hexagonal (customizable) .

Grade: Commercially Pure Titanium Grade 1 (CP-1) .

Standard: ASTM B348, AMS 4940, UNS R50250, ISO 5832-2 .

Certification: ISO 9001 / (any additional certifications you have) .

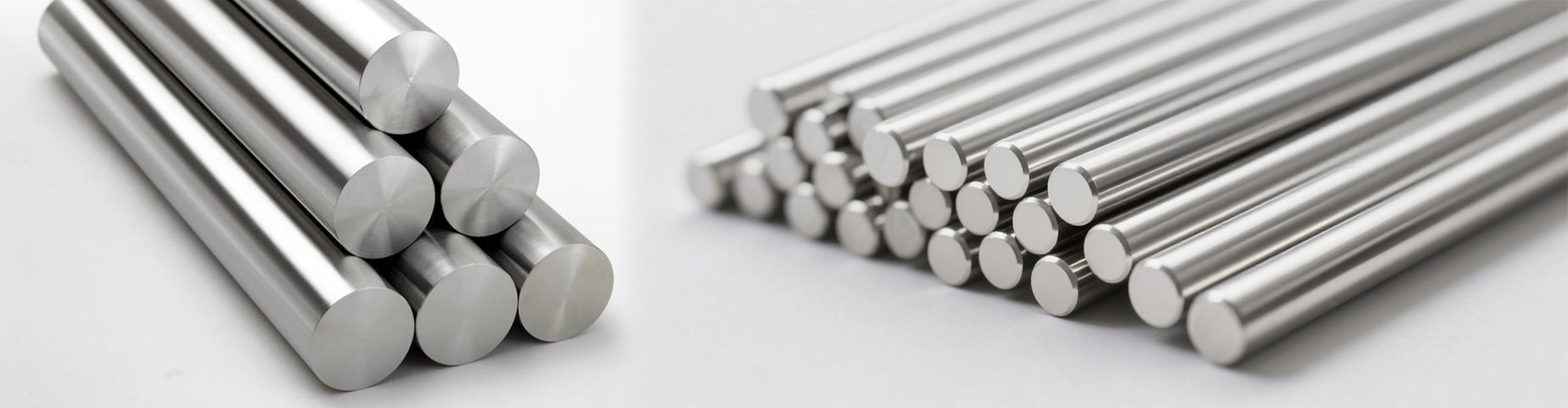

Finish: Polished / Bright / Pickled (customer preference) .

Regular Length: 2500–3000 mm (custom lengths accepted) .

Surface: Machined / Annealed / Cold Finished.

|

|

Details

GR1 Titanium Bar is made from commercially pure titanium (CP Grade 1), delivering exceptional corrosion resistance, excellent ductility, and formability. It is the softest and most easily worked of the pure titanium grades, making it ideal for forming, welding, machining, and fabrication in demanding environments. The low density combined with outstanding corrosion resistance makes it a preferred material in industries requiring longevity and durability.

Characteristics:

Gr1 titanium bars are valued for a unique combination of physical and chemical properties that set them apart from other metal materials:

- Excellent Corrosion Resistance— Resistant to seawater, chlorides, acids, and industrial chemicals, making it suitable for marine and chemical processing environments.

- High Purity Titanium— With minimal alloying elements, the gr1 titanium bar provides superior biocompatibility and chemical stability.

- Lightweight with Good Strength— Offers an excellent strength-to-weight ratio, helping reduce overall component weight without compromising performance.

- Outstanding Formability and Weldability— Easily machined, cold-worked, and welded, making it suitable for complex fabrication processes.

- Non-Magnetic and Non-Toxic— Ideal for medical, laboratory, and sensitive industrial applications.

Chemical Composition

| Element | Content(wt%) |

| Titanium (Ti) | Balance (≥99.5%) |

| Oxygen (O) | ≤ 0.18 |

| Iron (Fe) | ≤ 0.20 |

| Carbon (C) | ≤ 0.08 |

| Nitrogen (N) | ≤ 0.03 |

| Hydrogen (H) | ≤ 0.015 |

Mechanical Properties (Annealed Condition, Typical Room Temperature Values)

| Property | Standard | Requirement (Min.) Typical Range |

| Tensile Strength (Rm) | ≥ 240 MPa | 240 – 350 MPa |

| Yield Strength (Rp0.2) | ≥ 170 MPa | 170 – 310 MPa |

| Elongation (A) | ≥ 24% | 30% – 40% |

| Reduction of Area (Z) | ≥ 30% | 50% – 65% |

| Brinell Hardness (HB) | – | ≤ 120 |

| Modulus of Elasticity (E) | – | Approx. 106 GPa |

Please Note: Exceptionally high elongation is the most prominent feature of Gr1, signifying its superior cold formability.

Physical Properties

| Property | Value |

| Density | Approx. 4.51 g/cm³ (~57% of steel) |

| Melting Point | Approx. 1668 °C |

| Thermal Conductivity | Approx. 16.4 W/(m·K) |

| Coefficient of Thermal Expansion (20-100°C) | Approx. 8.6 × 10⁻⁶ /K |

| Specific Heat Capacity | Approx. 520 J/(kg·K) |

| Electrical Resistivity | Approx. 0.42 μΩ·m |

Corrosion Resistance (Key Characteristics & Applications)

| Environment / Medium | Corrosion Resistance Rating | Typical Application Scenarios |

| Neutral & Oxidizing Media | Excellent | Seawater, brine, wet chlorine, nitric acid |

| Atmospheric Environments | Excellent | Marine, industrial, and rural atmospheres |

| Organic Media | Good to Excellent | Chlorinated hydrocarbons, organic compounds (except anhydrous methanol) |

| Reducing Acids | Poor | Non-oxidizing hydrochloric, sulfuric, phosphoric acids |

| Key Mechanism | Formation of a dense, stable titanium dioxide (TiO₂) passive film with self-healing capability. | |

| Special Risks | Rapid oxidation or even ignition can occur in dry chlorine gas, fuming nitric acid, etc. Crevice corrosion requires attention in tight gaps. |

Common Applications of Gr1 Titanium Bar

Due to its versatility and reliability, the gr1 titanium bar is widely used across multiple industries:

- Chemical Processing Industry— Used in heat exchangers, reactors, piping systems, and storage tanks where corrosion resistance is essential.

- Marine and Offshore Engineering— Suitable for components exposed to seawater, salt spray, and high humidity environments.

- Medical and Healthcare Equipment— Commonly used in surgical instruments, medical devices, and implants due to its excellent biocompatibility.

- Aerospace and Aviation— Applied in non-load-bearing structural parts and auxiliary components requiring lightweight materials.

- Electroplating and Anodizing Equipment— Preferred for racks, fixtures, and electrodes because of its resistance to chemical attack.

- Industrial Manufacturing and Fabrication— Used for custom machined parts, fasteners, and precision components.

Manufacturing Quality and Standards

Each gr1 titanium bar is produced using advanced melting and forming processes to ensure uniform structure and stable performance. Strict quality control procedures are implemented throughout production, including:

- Chemical composition analysis

- Mechanical property testing

- Dimensional inspection

- Surface quality inspection

Products are typically supplied in accordance with recognized international standards such as ASTM, ISO, or equivalent specifications, ensuring reliability and global acceptance.

Why Gr1 Titanium Bar Is a Reliable Material Choice?

With its combination of purity, corrosion resistance, and ease of fabrication, the gr1 titanium bar remains one of the most trusted materials for demanding environments. Its proven performance across chemical, marine, medical, and industrial sectors makes it a preferred choice for engineers and manufacturers worldwide.

The production process of titanium bar

1. Raw Material Preparation

The production of titanium bars begins with titanium sponge, which is produced from titanium dioxide (TiO₂) through the Kroll process. The sponge is crushed, screened, and chemically analyzed to ensure compliance with required purity levels. Alloying elements such as aluminum, vanadium, molybdenum, or iron may be added depending on the specified titanium grade (e.g., Grade 2, Grade 5).

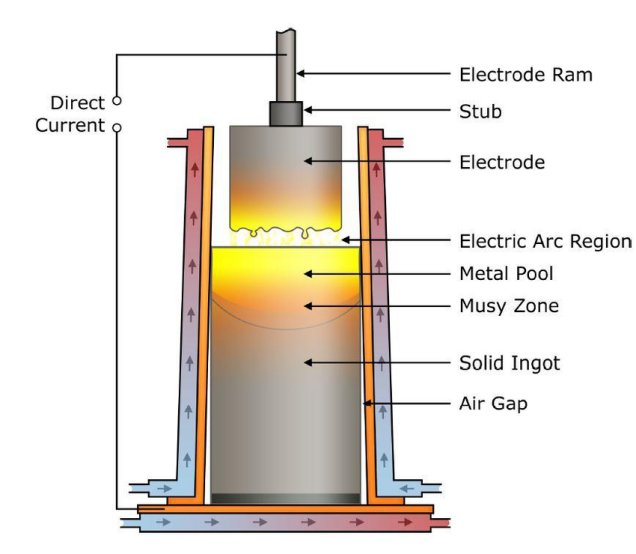

2. Melting and Alloying

Prepared titanium sponge and alloying elements are melted under a high-vacuum or inert argon atmosphere to prevent contamination from oxygen, nitrogen, and hydrogen.

Common melting methods include:

Vacuum Arc Remelting (VAR)

Electron Beam Melting (EBM)

The molten metal is cast into titanium ingots. For critical applications, the ingots may undergo double or triple remelting to ensure chemical homogeneity and structural integrity.

3. Ingot Conditioning

After solidification, the ingots are:

Surface-inspected.

Machined or ground to remove surface defects.

Ultrasonically tested for internal flaws.

This step ensures the ingot is free from cracks, inclusions, or segregation before further processing.

4. Hot Working (Forging or Rolling)

The conditioned ingots are reheated to a controlled temperature (typically 800–1100°C, depending on the grade) and then mechanically deformed.

Processing methods include:

Hot forging for large-diameter bars.

Hot rolling for smaller diameters.

This step refines the grain structure, improves mechanical properties, and reduces the ingot into billets or rough bars.

5. Bar Forming

The billets are further processed into final bar shapes using:

Hot rolling.

Hot extrusion.

Combination of rolling and forging.

Dimensional control is carefully monitored to meet customer specifications for diameter, straightness, and tolerance.

6. Heat Treatment

Titanium bars undergo heat treatment to achieve the desired mechanical properties.

Typical treatments include:

Annealing – improves ductility and stress relief

Solution treatment and aging – enhances strength (mainly for alloys like Ti-6Al-4V)

Heat treatment is performed in vacuum or inert gas furnaces to avoid oxidation.

7. Straightening and Sizing

After heat treatment, bars may experience slight distortion. They are:

Straightened mechanically.

Precision-sized through peeling or centerless grinding (if required).

This ensures tight dimensional accuracy and smoothness.

8. Surface Finishing

Surface finishing improves appearance, cleanliness, and usability.

Common finishing methods:

Pickling.

Grinding.

Polishing.

Turning (peeled bars).

The final surface condition depends on customer or industry standards.

9. Inspection and Quality Control

Each titanium bar is subjected to strict quality inspections, including:

Chemical composition analysis.

Mechanical testing (tensile, yield, elongation).

Ultrasonic testing.

Dimensional inspection.

Surface defect examination.

All inspections are conducted according to standards such as ASTM, AMS, ISO, or EN.

10. Cutting, Packaging, and Dispatch

Approved bars are cut to required lengths, labeled with heat numbers and grade details, and packed using protective materials to prevent contamination or damage during transportation.

Application:

Chemical and petrochemical engineering;

Marine engineering and shipbuilding;

Aerospace;

Medical and biological implants;

Energy and power;

Automotive industry;

Sports and leisure products;